Data Acquisition

Sortation solutions for parcel processing in an automated warehouse environment.

Post and parcel businesses know that eCommerce is increasing at a rapid rate. Couple that with heightened processing and delivery costs, plus consumer expectations for free shipping. Meeting these demands while remaining competitive is a challenge for every business in the industry. Additionally, there is greater variation in package size and material due to efforts to economize. How can postal, parcel, and eCommerce businesses effectively process all the packages and remain profitable? More efficient sortation solutions are part of the answer and automated data acquisition is the first step.

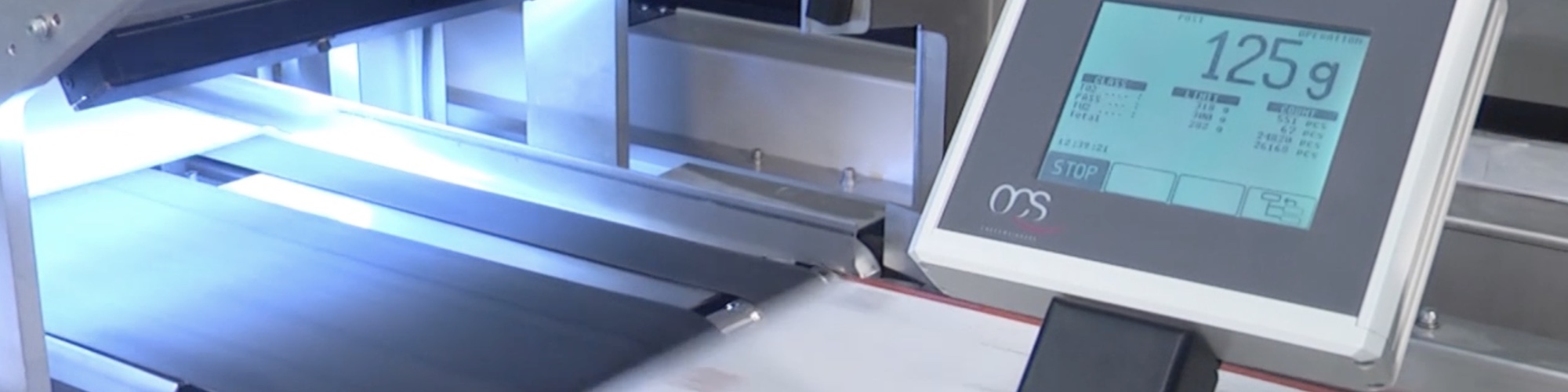

Every successful automation process begins with data acquisition. Parcel processing is no exception. Gathering data on each parcel means reading its attributes, such as weight, dimensions, barcodes, and written text. This information needs to be accessed before the parcel can be processed. In an automated data acquisition solution, scanners and readers do this work. OCR readers handle both machine and hand-printed labels whether they include a barcode or not. The addition of an OCR Reject Processor significantly reduces the number of rejected parcels due to unreadable, handwritten labels. Situated along the automation line, they "read" the parcels, matching them to a customer database. This data is then applied to a "sorter induction" system.

Sorter induction refers to the processing of parcels so that they can be sorted. This includes weighing the package, reading the label, recording it, and moving it to the sorter line. Sorter induction introduces parcels and packages to the sorting system to be routed to the correct shipping lane/zone. Traditionally, this work was done manually. That meant high labor, low speed, and lots of room for human error. However, automation is now the norm. The automated warehouse uses inline cameras for high-resolution image acquisition, OCR/BCR recognition software, scanners, and sorters for processing parcels to increase speed while eliminating errors.

Data acquisition and sorter induction.

Sortation solutions with automated data acquisition and a sorter induction system provide numerous benefits to a postal or parcel distribution center. These include:

- Greater efficiency and productivity

- Elimination of human error in the misreading and recording of data

- Faster throughput

- Increased capacity

- Decreased staffing needs

- Space savings

- Lower costs

- High reliability

BlueCrest provides proven, high-quality induction products that are expected to increase productivity demands and decrease costs.

BlueCrest Sortation Solutions with Sorter Induction

A BlueCrest Sorter Induction System will satisfy induction requirements for your distribution operation. It is available as an in-line or offline system. Automated parcel processing speeds range from 200 to 12,000 parcels per hour. This provides on-demand or non-stop parcel performance with little or no labor intervention. All BlueCrest solutions are custom designed for the user. They are modular and can include any/all of the following components:

-

Sorting Systems

- The TrueSort® is an ultra-flexible solution for parcel sorting that provides outstanding throughput rates. Plus, it provides a choice of multiple sorting technologies including the tilt tray, bomb bay, push tray, shoe sorter, and others.

- The VariSort™ is a hybrid sorting solution designed to sort everything from mail, difficult-to-sort flats, and small parcels.

- SortAssist™: A fully featured manual sort solution powered by SortEngine® 360 software. Produces bag level manifests for upload. Includes all the functionalities of a large Parcel Sorter around data IT.

-

Data Capture

- OneSort® automated data capture solutions provide all of the automation needed for enhanced parcel processing and management.

- OneSort® automated data capture solutions provide all of the automation needed for enhanced parcel processing and management.

-

Flow

- Intelligent Parcel Gapping system was developed to provide an efficient and flexible solution for processing a mixed array of parcels, such as cartons, flats, and polybags, with precision at high throughputs.

- HS Roller Divert is a diverter for parcels, flats, and polybags that moves small parcels from the sortation line quickly.

-

Print & Apply

- Raptor™ is a high-performance Print & Apply labeling system that delivers a dramatic improvement in throughput, efficiency, and maintainability.

-

Software

- SortEngine™ 360: This innovative postal software architecture connects multiple sortation equipment types including letters, flats, mixed mail, and parcels.

- Sabre, SabrePlus: Advanced OCR reject processor significantly reduces first-pass rejects and increases 11-digit barcode assignments.

- Winsort® InProcessing sorting software for MLOCR, BCR (barcode reader), and custom systems.

BlueCrest sorter induction solutions provide a full end-to-end solution that minimizes manpower and maximizes throughput for any automated warehouse. All solutions are scalable, customized according to client needs, and fully supported. Our "BlueShirt Excellence" team provides service and support on all equipment and software purchases over the lifetime of the product.